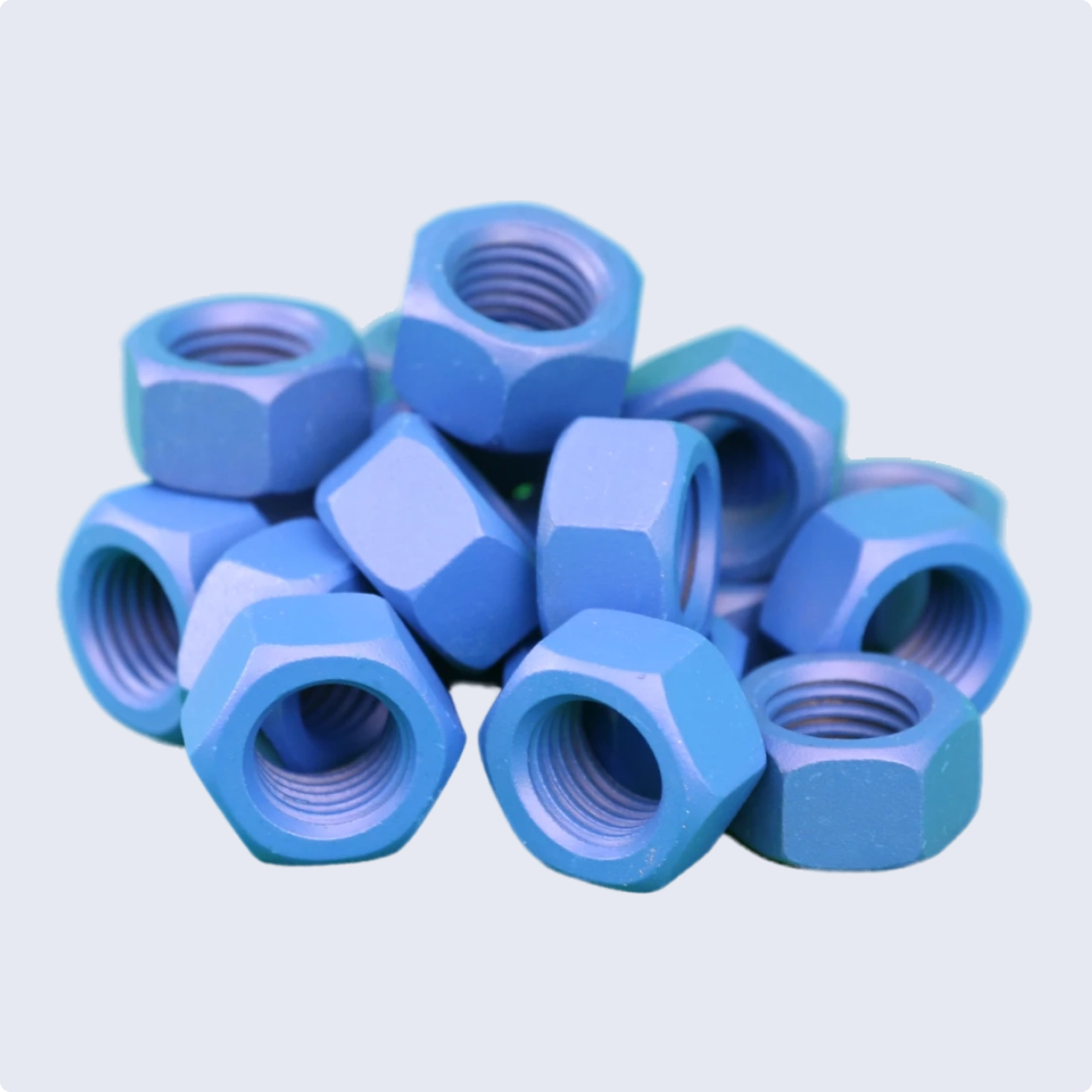

TRIPAC 2000 Blue

Product Overview

Description

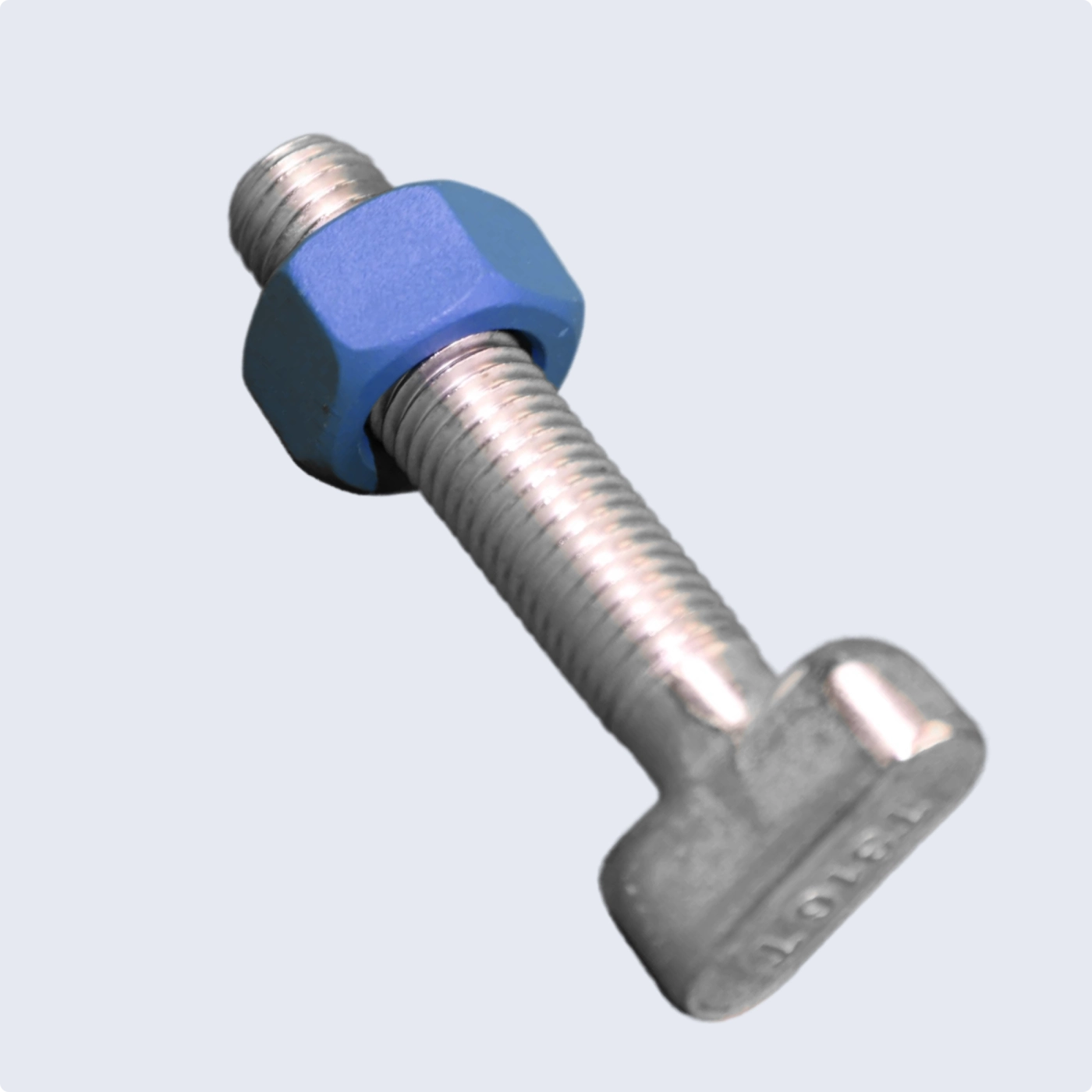

A Complete System

Coating Procedures:

1. Surface Preparation:

- All Surfaces Chemically Cleaned

- Abrasive Blasting with Alum. Oxide (120 Grit)

- Zinc/Nickel Primer Process Applied

- Baked

2. Coating:

- Multiple Coats of Fluoropolymer Coating Applied (1 mil) 1014/1424

- Air Dry For Minimum of 30 minutes

- Baked at 425 Degrees for 1 hour

- Quality control checked for uniform application and thickness. Appearance shall be free from any cracks, pinhole, runs, sags. Foreign matter, grit, rough particles or other surface imperfections.

Coating Properties:

TRIPAC 2000 Blue differs from traditional Fluoropolymer coatings in one very important aspect – it is a composite material. Lubricants with the lowest known coefficient of friction are combined in a matrix with high temperature organic polymers. United, these polymers form “Plastic Alloys” Having unique and desirable properties:

- Low friction; as low as 0.02

- Wear resistance; even under extreme pressure

- Corrosion and chemical resistance in most environments

- Weather resistance against sunlight

- Excellent lubrication to eliminate use of anti-seize

Other:

1000 Hours salt spray test (ASTM-B-117) Performed on bolts that have been torqued indicate that in some instances, some of the coating is removed from either the bolt head (by the wrench) or from the threads (by the nut). Even with this damage, the bolt shows minimum rusting and the nut is easily removed. Bolts protected by zinc plating and by hot dipped galvanizing show significant rusting and the nuts cannot be removed under the similar testing. Bolts used in this same testing are available for examination. Further information on physical and chemical properties is available upon request.

Technical Data

Submittal Builder

An Industry first! Create your own specification files or build your own project submittals. The data is always current, no more individual downloaded PDF files that can be dated.