Product Overview

Description

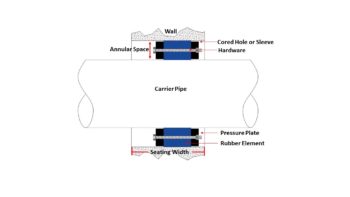

TRIPAC Pressio Modular Seals are an excellent choice to seal annular spaces/openings between wall, floor ceiling around a pipe or cable. Engineered for use as a permanent seal; the sealing elements are designed to resist aging and attack from ozone, sunlight, water and a wide range of chemicals.

A hydrostatic seal is easily engaged by compressing the links between both polyamide pressure plates. This action provides a gas and watertight closure of the annular space between medium pipe, casing pipe and core hole. The TRIPAC Pressio modular seal is rated at 20 psig (40 feet of head), which exceeds the performance requirements of most applications.

Type C (Carbon Steel Hardware)

Type S (316 Stainless Steel Hardware)

EPDM molded black rubber (50 ± 5 Shore A) standard rubber for cable or steel, cast iron, ductile iron and PVC pipes. Pressure plates polyamide 6-30. Operating Temperature: -40°F (-40°C) to +176°F (+80°C).

Type S (316 Stainless Steel Hardware)

EPDM molded black rubber (50 ± 5 Shore A) standard rubber for cable or steel, cast iron, ductile iron and PVC pipes. Pressure plates polyamide 6-30. Operating Temperature: -40°F (-40°C) to +176°F (+80°C).

Features and Benefits

- UV Resistant—Made of high quality materials

- Positive hydrostatic seal of 20 psig (40 feet of head)

- Fast mounting and installation—22 Model Sizes

- Retrofit applications—Applicable for various constructions

- Cost efficient solution—Quotes provided with spec and dimensions

- Good differentiation of the various rubber qualities

- Electrical isolation between pipe and sleeve

- Noise protection—Anti vibration application

- Easy stocking

- Radon tight

How to Order - Generate Quote

For assistance with Pressio Modular Seal selection for an application or general product ordering, please review below and provide the following information.

- Hole/Sleeve I.D.

- Pipe O.D.

- Model Number

- Number of Links

- Confirm Hardware: Carbon Steel or 316 Stainless Steel

- Use Sizing Program on TRIPAC Engineering Box App or Contact sales@tripacusa.com

Trouble Shooting

For assistance with trouble shooting a Pressio Modular Seal application in the field, please address the following. To streamline information to TRIPAC, please use the TRIPAC Engineering Box App and submit report.

- Your Name and Phone Number

- Order Number

- Model Size

- Number of Links Used

- Is Pipe Supported and How is Pipe Supported

- Did you use a torque wrench

- Was a power wrench used

- Was speed of wrench under 450 RPM

- Pipe Type and Pipe OD

- Hole/Sleeve ID

- Provide Annular Space Measurements around application

- Take Pictures

Technical Data

More Technical Details

Rubber / Seal Element

Industry:

Wastewater

Durometer:

50 ± 5 Shore A

Operating Temp MIN:

-40°F (-40°C)

Operating Temp MAX:

176°F (80°C)

Color:

Black

U.V. Resistant:

Yes

Pressure Plate

Industry:

Wastewater

Durometer:

50 ± 5 Shore A

Operating Temp MIN:

-40°F (-40°C)

Design:

Asymmetric

Color:

Black

U.V. Resistant:

Yes

Hardware: Bolt / Nut / Washer

Material:

Carbon Steel-Galvanized (Model C) or 316 Stainless Steel (Model S)

Allen Head:

IL-100 thru IL-315

Hex Head:

IL-325 thru IL-700

Lubrication

KTW, NSF

Lubrication Temp MIN:

-4°F (-20°C)

Lubrication Temp MAX:

212°F (100°C)

Model Size | Min. Links For Belt | Bolt Size | Bolt Head | Tool Size |

|---|---|---|---|---|

| IL-100 | 4 | M4 × 60 | Allen | 3mm |

| IL-200 | 4 | M5 × 70 | Allen | 4mm |

| IL-265 | 5 | M5 × 70 | Allen | 4mm |

| IL-275 | 4 | M5 × 70 | Allen | 4mm |

| IL-300 | 5 | M6 × 90 | Allen | 5mm |

| IL-310 | 5 | M6 × 90 | Allen | 5mm |

| IL-315 | 5 | M6 × 90 | Allen | 5mm |

| IL-325 | 6 | M6 × 100 | Hex | 10mm |

| IL-340 | 4 | M6 × 100 | Hex | 10mm |

| IL-360 | 5 | M6 × 100 | Hex | 10mm |

| IL-400 | 6 | M8 × 130 | Hex | 13mm |

| IL-410 | 5 | M8 × 130 | Hex | 13mm |

| IL-425 | 6 | M8 × 130 | Hex | 13mm |

| IL-440 | 6 | M8 × 130 | Hex | 13mm |

| IL-475 | 5 | M8 × 130 | Hex | 13mm |

| IL-500 | 5 | M10 × 150 | Hex | 17mm |

| IL-525 | 6 | M10 × 150 | Hex | 17mm |

| IL-575 | 5 | M10 × 150 | Hex | 17mm |

| IL-615 | 6 | M12 × 180 | Hex | 19mm |

| IL-625 | 5 | M12 × 180 | Hex | 19mm |

| IL-650 | 5 | M12 × 180 | Hex | 19mm |

| IL-700 | 6 | M12 × 180 | Hex | 19mm |

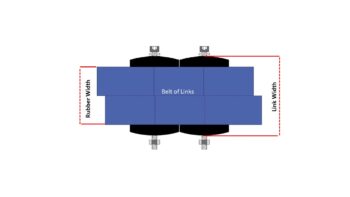

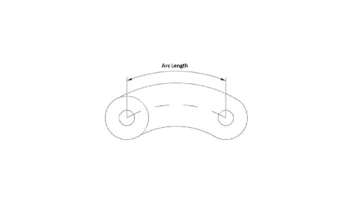

| Pressio Model Size | Sealing Range (Min) | Sealing Range (Max) | Arc Length | 6 | 2 | Rubber Width | Link Width | Min. Links For Belt | Min. Seating Width |

|---|---|---|---|---|---|---|---|---|---|

| IL-100 | .35" (9) | .49" (12.5) | 1.2" (31) | .98" (25) | 8.6" (219) | 1.7" (45) | 2.4" (60) | 4 | 2.4" (60) |

| IL-200 | .49" (12.5) | .62" (15.7) | 1.1" (30) | .84" (21.3) | 12.7" (323.9) | 1.7" (45) | 2.5" (63) | 4 | 2.5" (63) |

| IL-265 | .63" (16) | .79" (20) | 1.6" (41) | 1.97" (50) | 16" (406.4) | 1.7" (45) | 2.5" (63) | 5 | 2.5" (63) |

| IL-275 | .63" (16) | .79" (20) | 1.0" (25.6) | 0" (0) | 3.54" (90) | 1.7" (45) | 2.5" (63) | 4 | 2.5" (63) |

| IL-300 | .71" (18) | .88" (22.5) | 1.6" (41) | 1.7" (44.5) | 10.7" (273) | 2.6" (65) | 3.5" (90) | 5 | 3.5" (90) |

| IL-310 | .71" (18) | .88" (22.5) | 2.2" (57) | 2.4" (60.3) | 16" (406.3) | 2.6" (65) | 3.5" (90) | 5 | 3.5" (90) |

| IL-315 | .83" (21.1) | 1.1" (26) | 1.5" (38.4) | 1.4" (37) | 12.7" (323.9) | 2.6" (65) | 3.5" (90) | 5 | 3.5" (90) |

| IL-325 | .91" (23.2) | 1.2" (30) | 3.1" (79) | 5.2" (133) | 28" (711) | 2.6" (65) | 3.9" (100) | 6 | 3.9" (100) |

| IL-340 | 1.0" (25.5) | 1.3" (34) | 1.6" (41.4) | 1.2" (30) | 12.7" (323.9) | 2.6" (65) | 3.9" (100) | 4 | 3.9" (100) |

| IL-360 | 1.2" (32) | 1.6" (42) | 2.2" (55.1) | 1.6" (40) | 16" (406.4) | 2.6" (65) | 3.9" (100) | 5 | 3.9" (100) |

| IL-400 | 1.4" (36) | 1.8" (46) | 3.7" (93.1) | 5.5" (139.7) | 48" (1220) | 3.3" (85) | 4.9" (125) | 6 | 4.9" (125) |

| IL-410 | 1.4" (37) | 1.9" (48.5) | 2.7" (67.6) | 2.4" (60.3) | 12.7" (323.9) | 3.3" (85) | 4.9" (125) | 5 | 4.9" (125) |

| IL-425 | 1.1" (28) | 1.4" (37) | 3.7" (93.1) | 5.7" (144) | 48" (1220) | 3.3" (85) | 4.9" (125) | 6 | 4.9" (125) |

| IL-440 | 1.7" (44) | 2.2" (55) | 3.9" (99.7) | 5.5" (139.7) | 48" (1220) | 3.3" (85) | 4.9" (125) | 6 | 4.9" (125) |

| IL-475 | 1.6" (41) | 1.9" (48.5) | 2.7" (68.6) | 2.4" (60.3) | 48" (1220) | 3.3" (85) | 4.9" (125) | 5 | 4.9" (125) |

| IL-500 | 2.4" (60) | 2.8" (71.5) | 3.9" (100) | 2.9" (100) | 48" (1220) | 3.5" (90) | 5.5" (140) | 5 | 5.5" (140) |

| IL-525 | 2.2" (55) | 2.5" (63.5) | 3.9" (100) | 3.9" (100) | 48" (1220) | 3.5" (90) | 5.5" (140) | 6 | 5.5" (140) |

| IL-575 | 1.9" (48) | 2.3" (58) | 3.1" (79.3) | 3.5" (88.9) | 48" (1220) | 3.5" (90) | 5.5" (140) | 5 | 5.5" (140) |

| IL-615 | 3.2" (81) | 3.8" (98) | 6.1" (155.5) | 8.6" (219) | 118" (3000) | 3.9" (100) | 6.5" (165) | 6 | 6.5" (165) |

| IL-625 | 3.2" (81) | 3.8" (98) | 4.2" (106.7) | 3.5" (88.9) | 79" (2000) | 3.9" (100) | 6.5" (165) | 5 | 6.5" (165) |

| IL-650 | 2.7" (69) | 3.4" (86) | 4.2" (106.7) | 3.3" (84) | 79" (2000) | 3.9" (100) | 6.5" (165) | 5 | 6.5" (165) |

| IL-700 | 3.7" (95) | 4.3" (110) | 6.1" (155.5) | 6.0" (152) | 118" (3000) | 3.9" (100) | 6.5" (165) | 6 | 6.5" (165) |

Submittal Builder

An Industry first! Create your own specification files or build your own project submittals. The data is always current, no more individual downloaded PDF files that can be dated.