Casing Spacers/End Seals

Product Overview

Description

Casing spacers/isolators are used on long and short distance transmission pipelines for various purposes. When a pipeline intersects with a railroad right-of-way, highway, waterway or any other thoroughfare the pipeline usually passes under or is buried beneath the obstruction. For protection in these areas, the carrier pipe is placed inside a casing pipe in an effort to “double contain” the fluid that is passing through the carrier pipe. If a leak or break were to occur, the fluid would be directed to a safe distance away from beneath the thoroughfare. In fact, many local Governmental Agencies require this procedure almost anywhere when volatile or hazardous fluids are flowing through the carrier pipe.

Casing spacers/isolators are used to electrically isolate the carrier pipe from the casing pipe. In most cases a corrosion mitigation program is in place to protect the carrier pipe from the detrimental effects of the environment and surrounding soil. Any outside influence of stray electrons can render the corrosion mitigation completely ineffective. A casing spacer/isolator ensures that no metal to metal contact is made between the carrier pipe and casing pipe which ensures the integrity of the corrosion mitigation program.

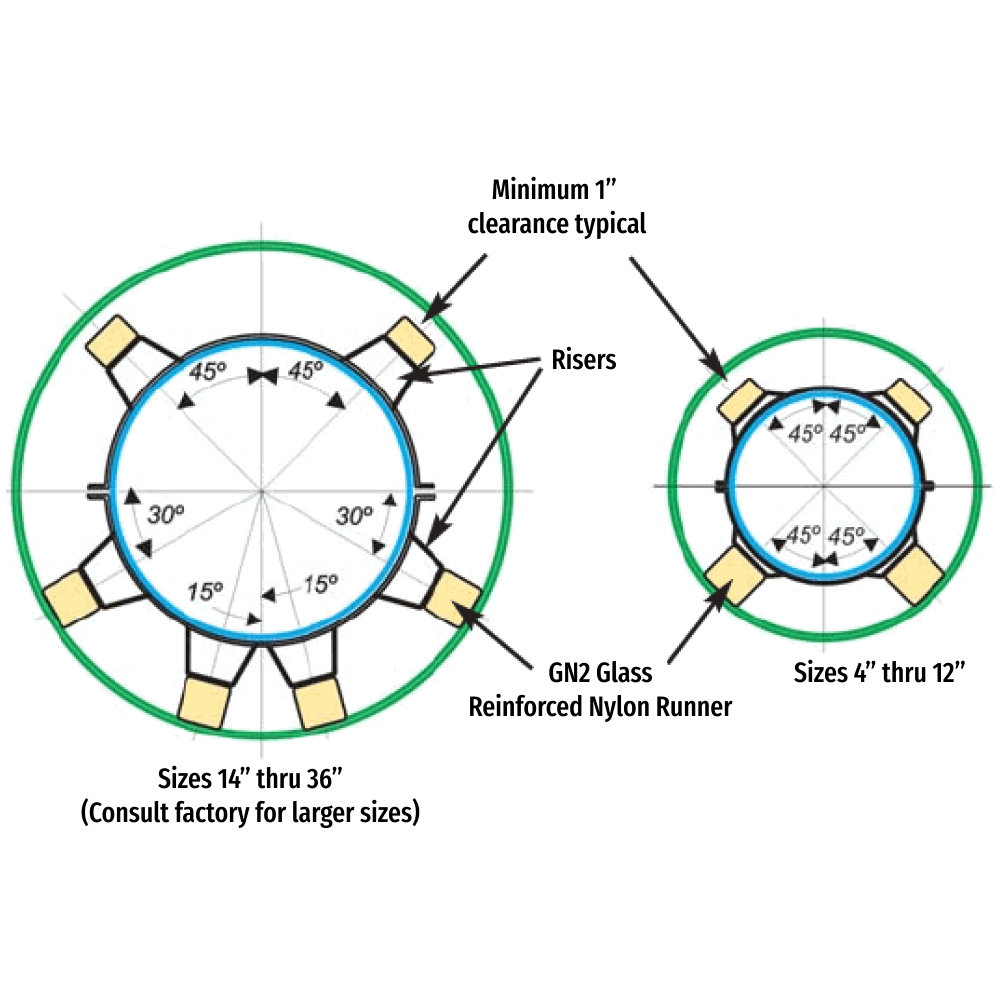

Casing spacers/isolators include low coefficient of friction runners on all surfaces making contact with the casing pipe which facilitates easy insertion of the carrier pipe into the casing, an especially important feature when making long pulls/pushes with heavy pipe. It’s important runners have a tensile strength of 17,600psi, a flexural strength of 25,300psi and a compression strength of 18,000psi.

For through wall penetrations, to center and support pipe for modular seal installations, casing spacers/isolators are also used. This keeps the weight off the seals, to avoid break down of the links (rubber and pressure plates) to avoid leaks.

Casing spacers are manufactured in steel (Coated and Stainless) and non-metallic options are available depending on pipe size and length or run.

End seals and modular seals are used in conjunction with casing spacers, to seal off the annular space of the carrier pipe and casing. End Seals are rubber seals that eliminate the possibility of foreign material entering the opening between the carrier and the casing pipe. They are available in EPDM 60, Buna-N, and neoprene material. End seals are suitable for new installations and retrofitting.

End Seals Overview

End Seals – Typical Models

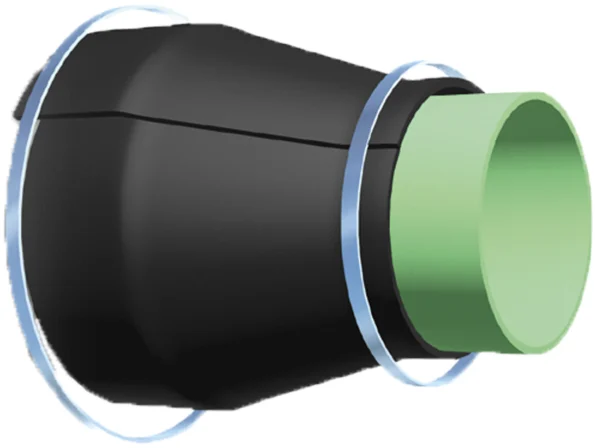

Model "C" End Seals (For New Installations)

Model “C” Custom Pull-on End Seals are designed to accommodate custom carrier/casing diameter combinations. They are made to customer supplied specifications so they may be used for any size casing/carrier differential. Manufactured from 1/8″ thick specially compounded synthetic rubber, Model “C” end seals are extremely robust, resistant to wide variations in environmental conditions while eliminating the possibility of foreign material entering the opening between carrier and casing pipes.

- Custom Made to Order

- Quick and Easy Installation

- Carrier Pipe Does Not Need To Be Centered Within Casing

- Screwdriver Is Only Tool Required for Installation

- Designed To Last for the Life of the Piping System

- Heavy Duty Stainless Steel Hose Clamps Supplied

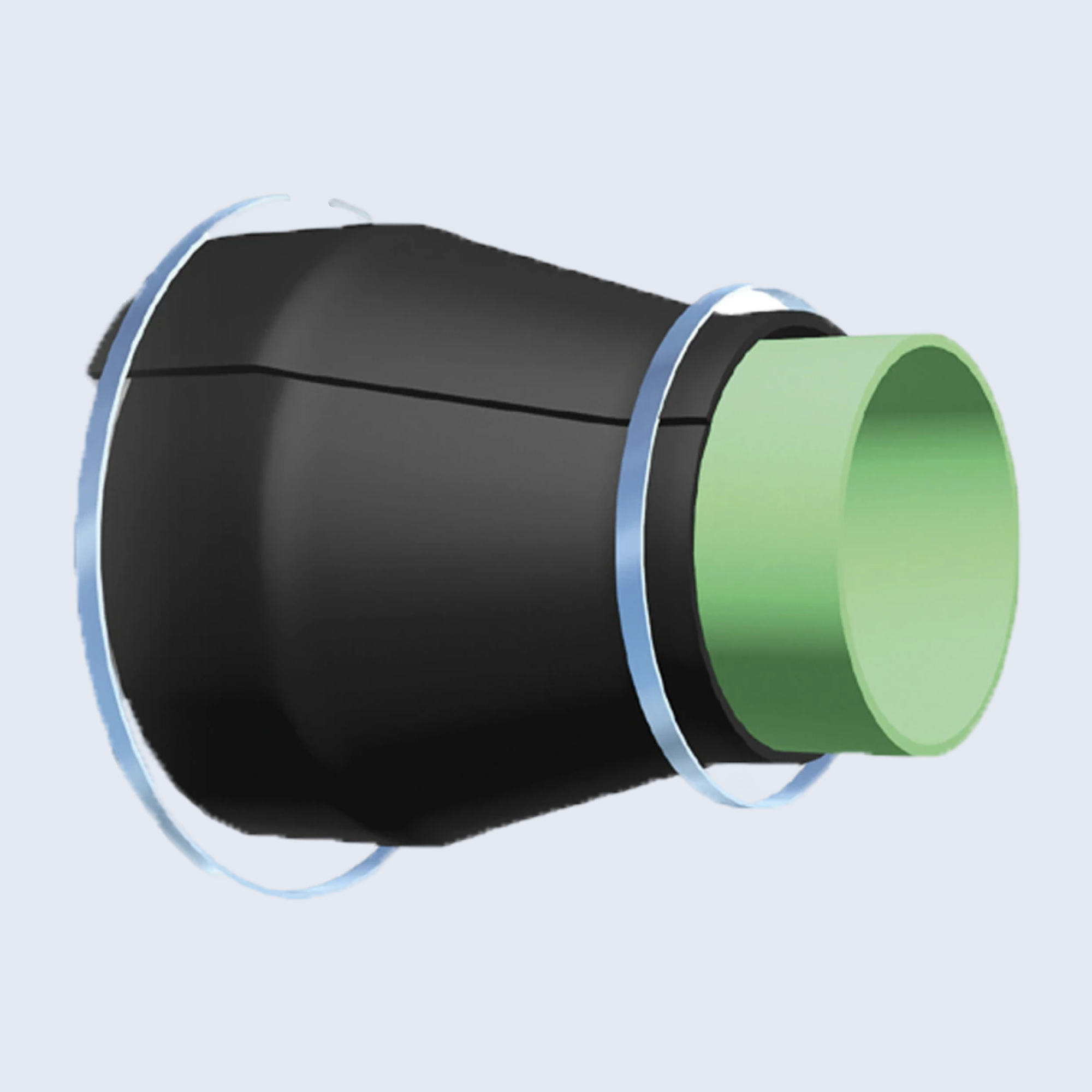

Model "W" Wrap Around End Seals (For New and Existing Installations)

Model “W” Wrap Around End Seals are designed to accommodate customer supplied specifications so they may be used for any size casing/carrier differential. Model “W” end seals are extremely robust, resistant to wide variations in environmental conditions while eliminating the possibility of foreign material entering the opening between carrier and casing pipes.

- Custom Made to Order

- Quick and Easy Installation

- Carrier Pipe Does Not Need To Be Centered Within Casing

- Screwdriver Is Only Tool Required for Installation

- Designed To Last for the Life of the Piping System

- Heavy Duty Stainless Steel Hose Clamps Supplied

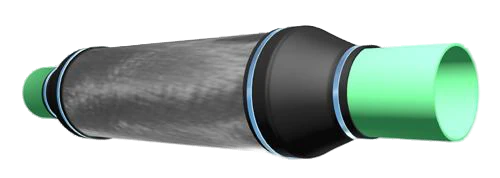

Pressio Modular Seals (For New and Existing Installations)

Installed at each end of pipeline casings or through wall penetrations. Modular seals provide

positive, hydrostatic protection against the entry of water, soil or other backfill materials and reduces corrosion and ice damage. Centered casing spacers should be used when installing

modular seals for casing or through wall penetration applications.

- Quick and Easy Installation

- Can Be Installed on Existing Centered Casing Installations

- Designed To Last for the Life of the Piping System

- Hydrostatic Seal - Seals up to 20psi

How to Order - Generate Quote

For assistance with gasket selection for an application or general product ordering, please review below and provide the following information.

- Quantity

- Type Finish (Metallic: Painted, Coated, Stainless or Non- Metallic)

- Band Width

- Runner Width

- Carrier Pipe O.D. (Type and coating thickness if applicable)

- Casing Pipe I.D. (Type and coating thickness if applicable)

- Carrier Pipe Joint/Bell O.D. (If applicable)

- Carrier pipe position within casing

- Length of crossing

- Contact sales@tripacusa.com

Technical Data

Submittal Builder

An Industry first! Create your own specification files or build your own project submittals. The data is always current, no more individual downloaded PDF files that can be dated.

How to Order - Generate Quote

- Quantity

- Type Finish (Metallic: Painted, Coated, Stainless or Non-Metallic)

- Band Width

- Runner Width

- Carrier Pipe O.D. (Type and coating thickness if applicable)

- Casing Pipe I.D. (Type and coating thickness if applicable)

- Carrier Pipe Joint/Bell O.D. (If applicable)

- Carrier pipe position within casing

- Length of crossing

- Contact sales@tripacusa.com